Bag Tag Injection Molding Mini-Project

Summary

As part of a small team, I designed and manufactured plastic Notre Dame monogram tags.

Skills

CAD (SolidWorks); Injection molding

Team Size

3 (myself and two peers)

Category

Coursework: Engineering Analysis of Manufacturing Processes (AME 50542)

Detailed Breakdown

The goal of this project was to become familiar with the plastic injection molding process by designing and producing a small plastic accessory. My teammates and I decided to produce a bag tag for use on backpacks, keychains, and suitcases. We selected the iconic Notre Dame monogram logo as the focus of our design.

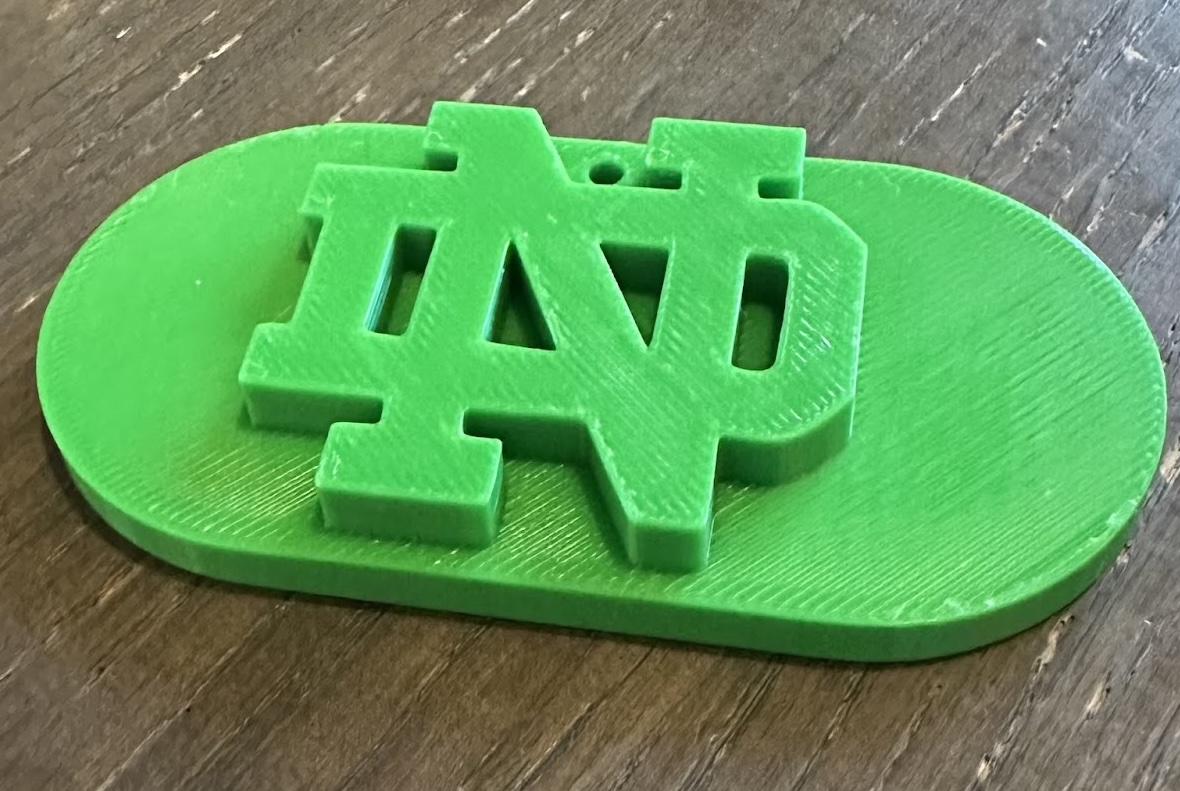

After some initial brainstorming, we created a CAD model and 3D printed a physical mockup of the part.

Original prototype of the bag tag. We relocated the hole and repositioned the monogram after this initial prototype.

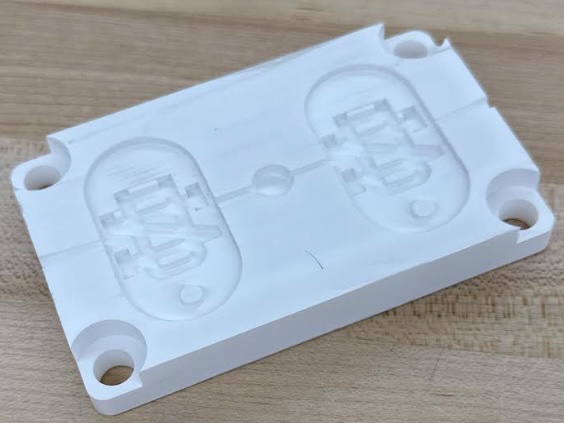

After adjusting and finalizing the design, we proceeded to create the mold necessary to produce the part. Our mold is divided into two halves: a featured side, which includes two copies of the part's negative image, and a completely flat side. We chose this approach in order to prevent weld lines, which is a reasonable choice for this relatively simple design. We designed sprue and runner channels for efficient and even delivery of molten plastic into the injection cavity. The mold also incorporates critical features such as holes for mounting pins and a pressure-relief hole to maintain stable pressure within the mold.

For this project, we were required to make the molds by 3D printing instead of by CNC-milling them out of metal. We used a tough resin SLA process for its fine print resolution and ability to withstand high compressive pressures without fracturing.

The 3D printed mold.

The first few parts came out looking exactly as we had hoped. Since we had made the molds out of a polymer resin instead of metal, however, the mold began to degrade rather quickly. During part ejection, the solidified plastic components caused visible material removal from the mold surfaces. This surface degradation created unwanted flash and dimensional inaccuracies in subsequent parts, with tolerances decreasing progressively with each cycle. While it is certainly possible to finetune the injection molding process (e.g., reducing injection pressure and melt temperature) to extend mold life, transitioning to a metal mold would provide better long-term repeatability and higher quality pieces overall.

A selection of some of the parts we produced. In total, we made about 25 parts. Some parts came out higher quality than others. For example, the lowerightmost part was the result of lowering injection pressure too much in an effort to reduce mold wear.